Cold Weather Charging of Lithium-Ion Batteries: Real-World Lessons from the Meshtastic Community

Intro: When Theory Meets Reality

Ask almost any battery expert, and they’ll tell you one thing for sure: don’t charge lithium-ion batteries below freezing. Cold charging is often blamed for lithium plating, dendrite formation, internal resistance buildup, and ultimately, cell failure.

But what if we told you that in two years of real-world off-grid deployments—with winter temperatures not uncommonly approaching −40 °C—we’ve seen none of that?

This article shares our experience from the trenches: the Meshtastic community, building and maintaining solar-powered, off-grid IoT nodes in the Canadian Rockies.

Who We Are & What We Built

Over the past two years, we’ve deployed dozens of Meshtastic LoRa nodes using nRF52-based microcontrollers (primarily the RAK WisBlock series, but others too). These nodes are spread across:

- 3 mountaintop locations (above 7000 ft)

- A handful of rural setups across Southern Alberta

- Multiple town-based nodes in Calgary and Okotoks

Interesting fact: One of those mountain nodes previously held the Meshtastic point-to-point range record at 254 km—proof of just how well LoRa can perform with the right elevation and conditions.

Most of these systems use standard unprotected 18650 Li-ion cells (3000–3500 mAh) and LiPo flat packs with basic protection circuits. Power comes from solar panels ranging from 1 W to 6 W, with average charging currents typically below 200 mA, occasionally peaking around 300 mA on a good day.

And the results? Zero failures.

Our Field Data

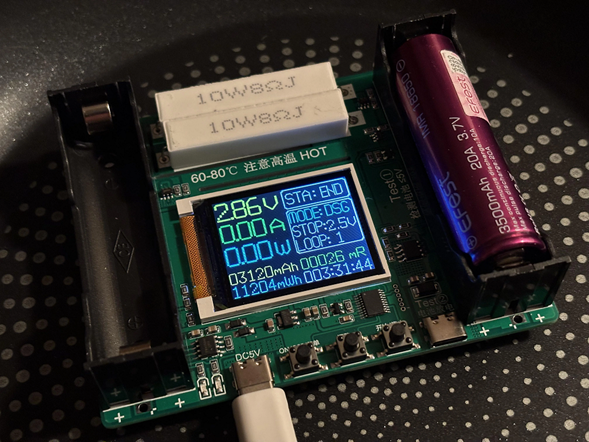

One node’s battery (an eFest 3500 mAh vape cell) was tested after two full winters:

- Remaining capacity: ~3100 mAh (brand-new tests ~3300 mAh)

- Internal resistance: 26 mΩ (rated: 30 mΩ)

- Still well within spec, with no signs of degradation or dendrite-related issues.

We were expecting problems. We kept waiting for failures. They never came.

What We Considered (But Didn’t Need)

- Bimetallic switch heaters – too power-hungry for solar setups

- Thermistor-triggered charge cutoffs – not helpful when devices spend months below freezing

- LTO or LiFePO₄ battery swaps – these have their uses, but the batteries and solutions to charge them can be costly and/or difficult to source. Keep reading further for Lithium Titanium Oxide (LTO) info.

Eventually, we just deployed the nodes and watched. The results held strong.

Why These Batteries Aren’t Failing

Here’s what we think is working in our favor:

1. Low Charge Currents

Most of our systems charge at < 0.1 C, often well below 0.05 C. Theoretical “safe” cold charge rates hover around 0.02 C. For those that want added safety, you can increase your battery capacity in line with you max charge rate to reach that theoretical safe limit.

For example: a RAK19007 board maxes at 350 mA charge current. Increasing battery capacity to at least 17 500 mAh brings it in line with the theoretical safe rate of 0.02 C — However thus far, we haven’t found this necessary. In most cases, this is overkill.

2. Charging Generates Heat

Even small charging currents create a bit of heat, especially in small enclosures. That can bump the battery’s temperature a few degrees higher than the outside air.

3. Discharge Happens at Night

Since solar charging only occurs during the day, charging tends to coincide with the warmest part of the day, while discharging occurs during the coldest. That natural cycle works in your favor.

4. Passive Solar Gain

Sunlight on small plastic boxes = heat trap. Even in frigid ambient conditions, internal temps can rise significantly with the right sun exposure.

But Doesn’t Cold Still Affect the Battery?

Absolutely. Cold temporarily reduces capacity. A battery that’s 30% full at -30°C may hit its undervoltage protection limit early, shutting down your device. But the damage isn’t permanent. As soon as temps rise, capacity returns.

This is why we recommend sizing your battery with reserve capacity, especially for deep winter use. Around 3000mAh seems to be a realistic MINIMUM for reliable performance in our conditions. Depending on region, YMMV.

Use the Right Platform: nRF52 vs ESP32

All our tests were done on nRF52-based boards, which sip power and are well-suited to small batteries and cold charging. By contrast, ESP32 boards use 5–10× more power, meaning they require bigger batteries, higher charge currents, and stricter thermal management. We don’t recommend applying our findings directly to ESP32 setups without further testing.

When to Consider LTO Cells

For mission-critical nodes in remote areas that can’t be serviced for months, we’ve started using Lithium Titanate (also known as Lithium Titanium Oxide or LTO) cells.

They’re not for every setup, but they offer:

- Safe charging even at −30 °C

- 10× longer cycle life

- Fast charge capability

- Exceptional toughness

- Small, reliable form factor

The tradeoffs? Price and availability. Use LTOs where they count—elsewhere, standard lithium-ion is usually more cost-effective.

We recommend the Voltaic Systems multi-chemistry MPPT charger for LTO/solar setups.

NOTE: Stock is sometimes sold out, but usually replenishes. Use the waiting list.

Design Tips for Cold-Weather Solar Charging

1. Panel Angle Matters

- In icy or wet snow climates: tilt steeply to shed buildup

- In dry, powdery areas (like the Rockies): snow buildup is less of an issue, but tilt still affects daily yield

Check out this reference study for optimal angles: NAIT Solar Panel Angle Report (PDF)

2. Cold = Higher Panel Efficiency

PV panels love the cold. Lower temperatures reduce internal resistance and improve output. Snow-covered ground also reflects sunlight—increasing incident light on panels and sometimes boosting output beyond their rated wattage.

Scientific Backing: Is This Supported by Research?

Yes— kind of. It’s widely documented that cold charging can cause lithium plating and dendrite growth, which over time increases internal resistance and reduces capacity. But the severity depends on multiple factors:

- Charge rate

- Temperature

- Battery age and chemistry

- Cycle count

- Cell quality

The best way to detect dendrites is via NMR spectrometry or imaging, which is far outside the reach of the average hobbyist. However, internal resistance is a solid proxy—and ours have stayed within factory spec.

Further Reading

- Lithium deposition and resistance — ScienceDirect (2025)

- Cold charging and capacity fade — PMC

- Safe cold charging strategies — ScienceDirect

Key Takeaways

If you’re building low-power, solar-charged IoT systems for cold climates, charging below freezing may not be as risky as you’ve been led to believe—as long as you:

- Use high-quality cells with low internal resistance

- Keep charge currents low

- Design for extra capacity buffer

- Enclose and orient your node for thermal gain

- Use nRF52-class microcontrollers (not ESP32)

- And for ultra-cautious builders? Add total battery capacity, or use LTO chemistry.

Thanks to the Meshtastic Community

This post wouldn’t be possible without the countless tinkerers, engineers, hobbyists, and weekend hackers in the Meshtastic community. Your ideas, shared data, and experiments have shaped this knowledge over years of collective testing. Too many names to list—but this is your story, too.